Gallery

Full Description

Customer Reviews

Sorry, our agreement with Woodcraft restricts us from shipping WoodRiver Planes to the U.S.

I own and recommend WoodRiver V3 planes. These planes are based on the reliable Stanley Bedrock design, are very well made, and have an excellent price point making them a "BEST VALUE."

All of our Woodriver bench planes receive our Cosman preparation service so they are100% ready to use out of the box. See prep service below for description of what we do.

The jointer plane (also known as a "try" plane) is used to straighten the edges of boards in the operation known as jointing and it can also be used to flatten the face of a board. Its long length is designed to 'ride over' the undulations of an uneven surface, skimming off the peaks, gradually creating a flat surface.

-

No. 7 Plane size: 2-7/8" W x 22" L with 2-3/8" W blade.

-

Includes our plane preparation service.

-

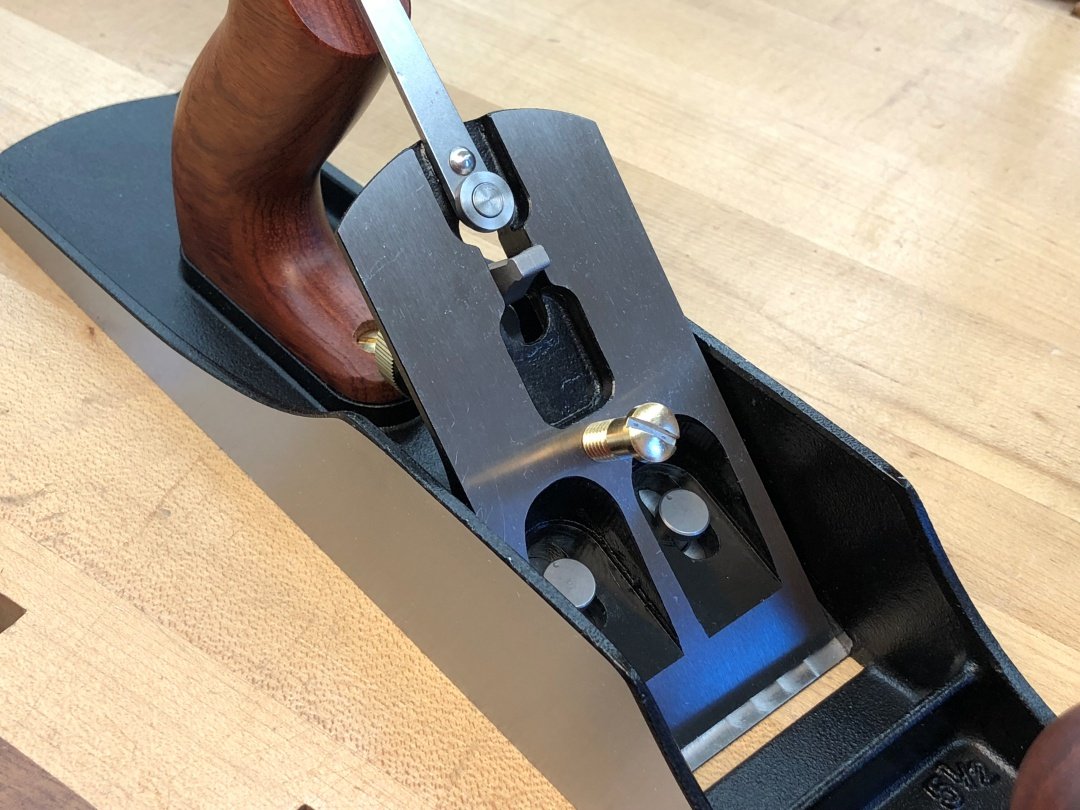

Heavy, stress-relieved ductile iron castings.

-

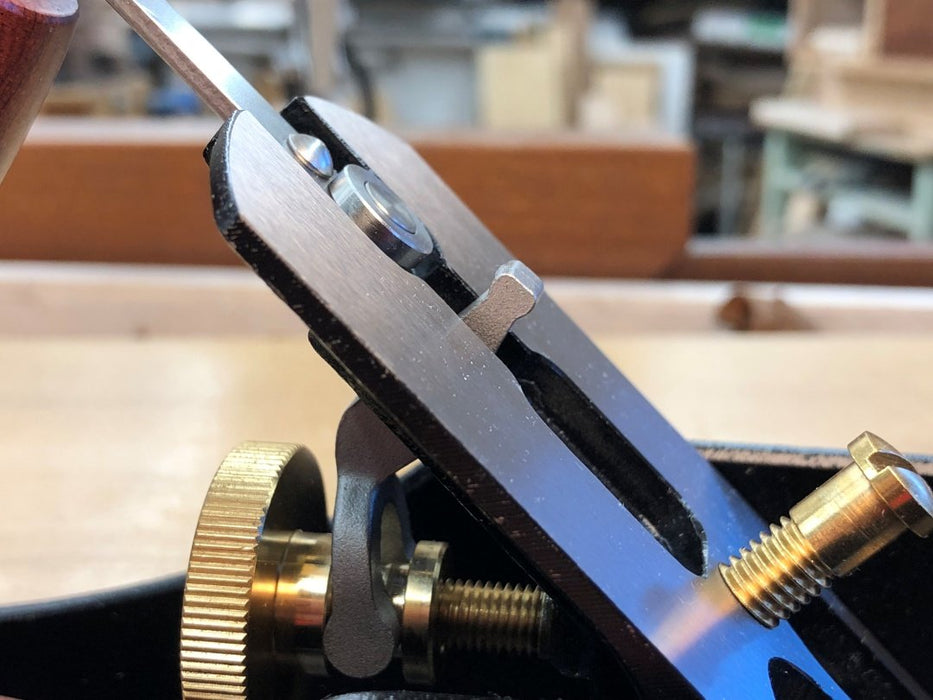

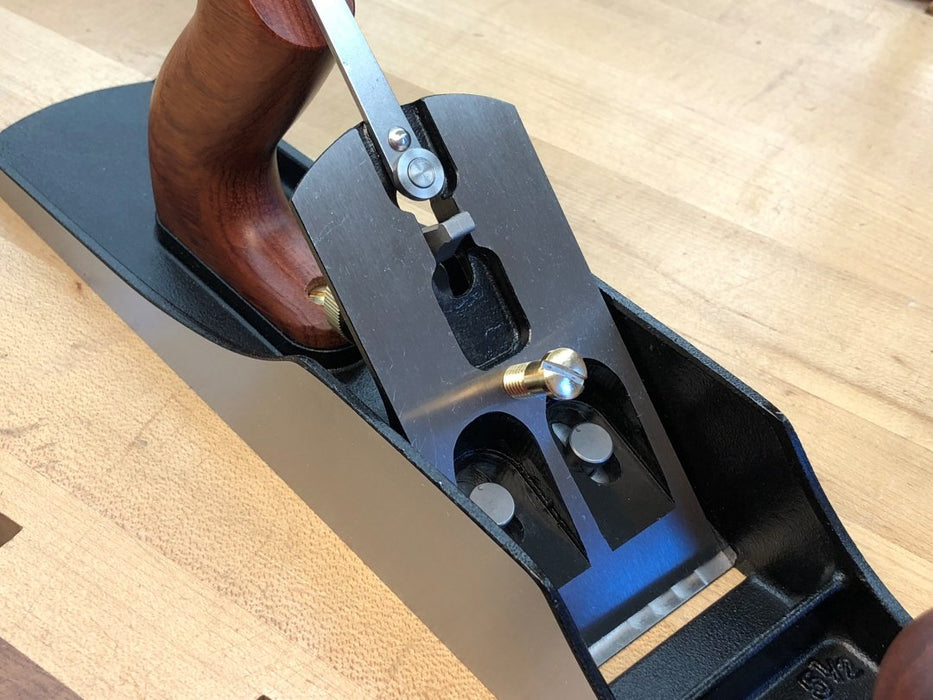

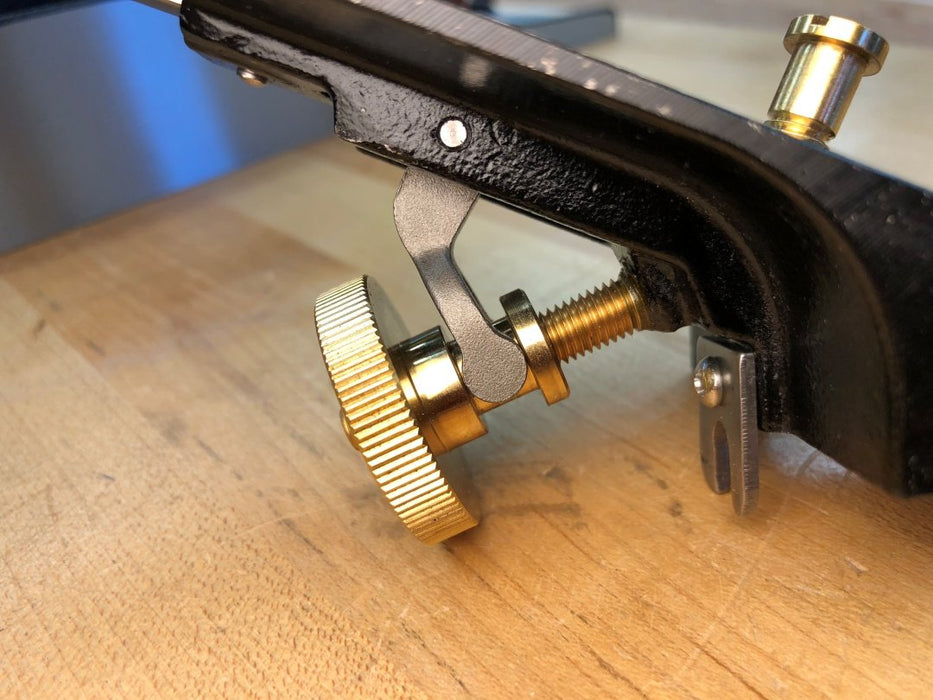

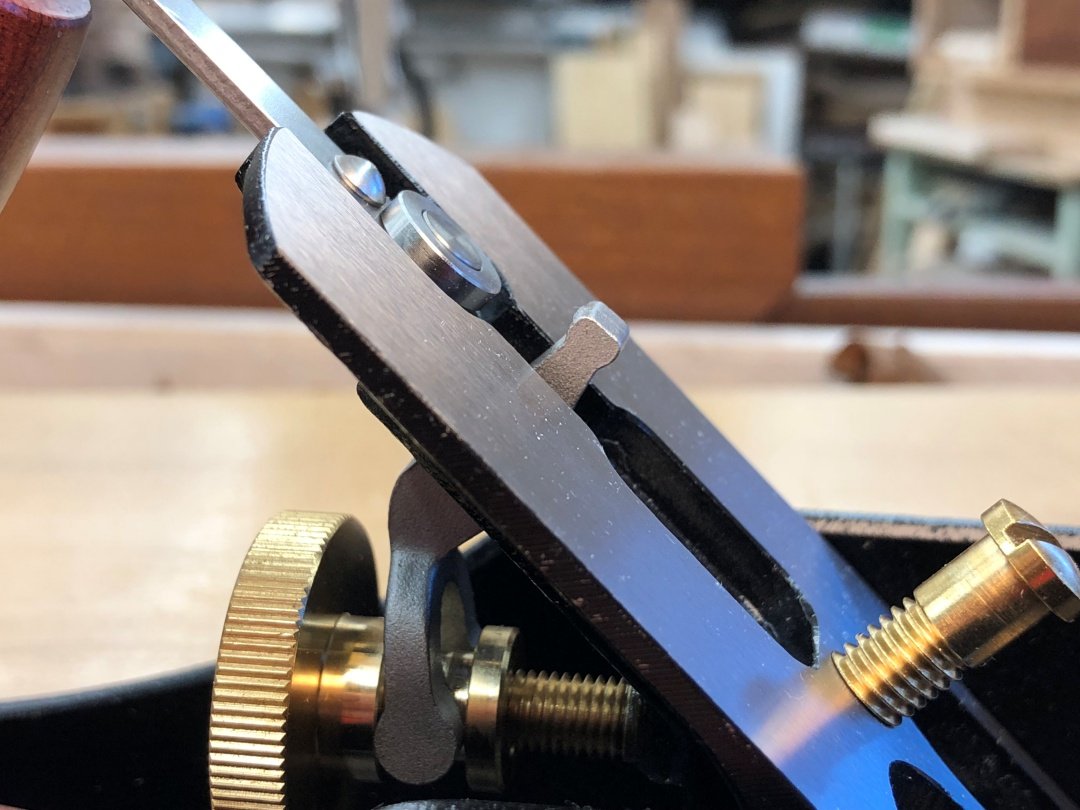

Fully machined adjustable frogs bedded at a 45 degree angle.

-

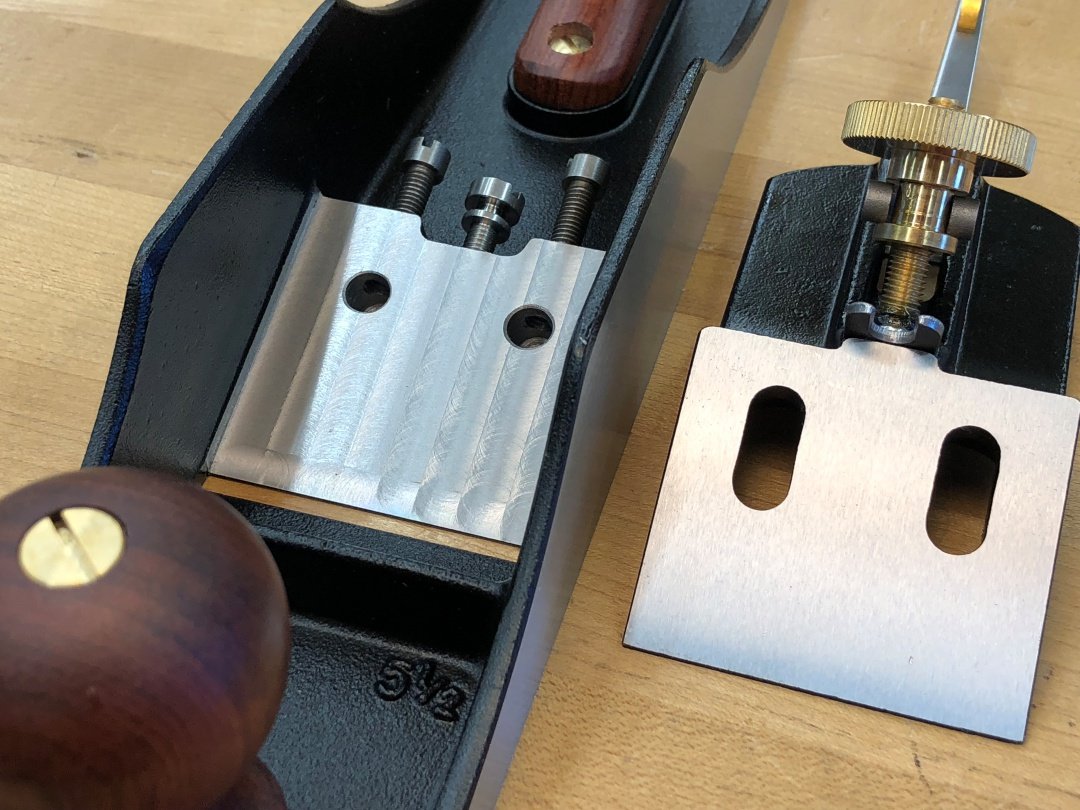

Thick steel blade and chipbreaker dampens vibration making solid planing.

-

Lightly finished Bubinga handles provide comfort and control.

-

Soles and sides are machined flat and square within tightly held tolerances.

Plane Preparation Service: All planes require some preparation. Our complete plane preparation service makes it so that no set-up is required by you. Your plane will be ready to use 'out-of-the-box! Our Plane Preparation Service includes:

- Flattening the sole to within +/- 0.0015 of an inch (0.038mm) of perfectly flat.

- Squaring the sides to within +/- 0.0015 of an inch (0.038mm) of 90 degrees to the now flat sole.

- Flattening the bottom of the the rear handle (tote) and the front handle (knob) and their boss so they mate properly with no movement.

- Chamfering / easing all edges and corners on the sole of the plane.

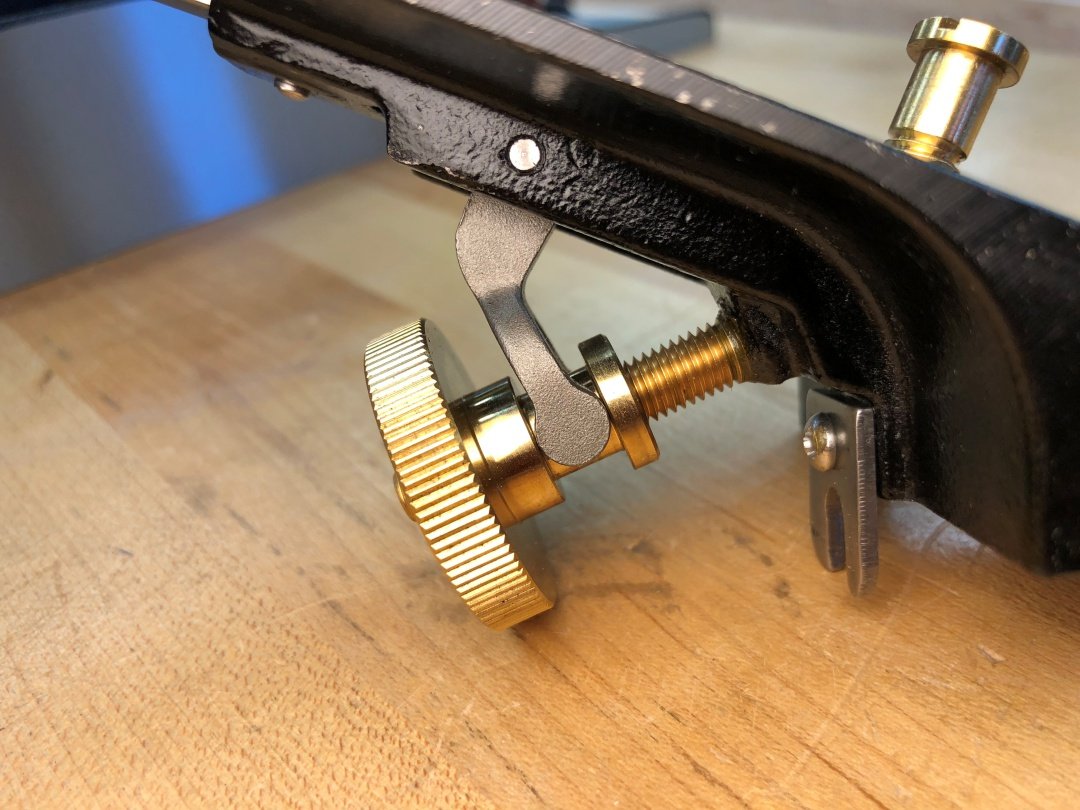

- Tuning the lateral adjustment lever so it moves freely.

- Applying a back bevel (Charlesworth ruler trick) to the back of the plane blade.

- Sharpen the blade using micro-bevels. Final polishing is done using 16,000 grit ceramic waterstone.

- Flattening the back edge of the lever cap so it mates properly to the chipbreaker.

- Flattening the leading edge of the chipbreaker so it mates properly to the blade.

- Testing the operation and set-up of the plane.

- Removing all of the shipping / packing grease and applying a light coat of camellia oil to all the metal surfaces to prevent rust.