Gallery

Full Description

Customer Reviews

I recommend and use 300 / 1000 grit, double-sided, diamond stones as an essential part of my tool sharpening method. Our diamond stones use only high quality mono-crystalline man-made industrial diamonds permanently adhered by electroplating to a thick, precision milled, steel substrate. Use the 300 side for flattening your water / ceramic sharpening stones and the 1000 side to establish your secondary bevel or your initial flattening grit.

We quality control test EVERY diamond stone we receive to determine if it's flatness is within our standard of being out of flat, either convex or concave, by no more than .004 (4 thousandths) of an inch. Stones outside our standards are rejected. Diamond stones within our standards are further graded as "Standard" or "Premium" quality.

The difference between our standard and the premium version diamond stones is the level of flatness. Diamond stones that test between .0016 and .004 (1.6 to 4 thousandths of an inch) out of perfectly flat, are graded as "standard." Diamond stones that test between .0000 to .0015 (perfectly flat to 1.5 thousandths of an inch) out of perfectly flat are graded as "premium."

Premium diamond stones are recommended for flattening the back of chisels and other applications where near perfect flatness is a must. Standard diamond stones are recommend for routine sharpening of plane blades and chisel cutting edges and general sharpening uses.

Product details

-

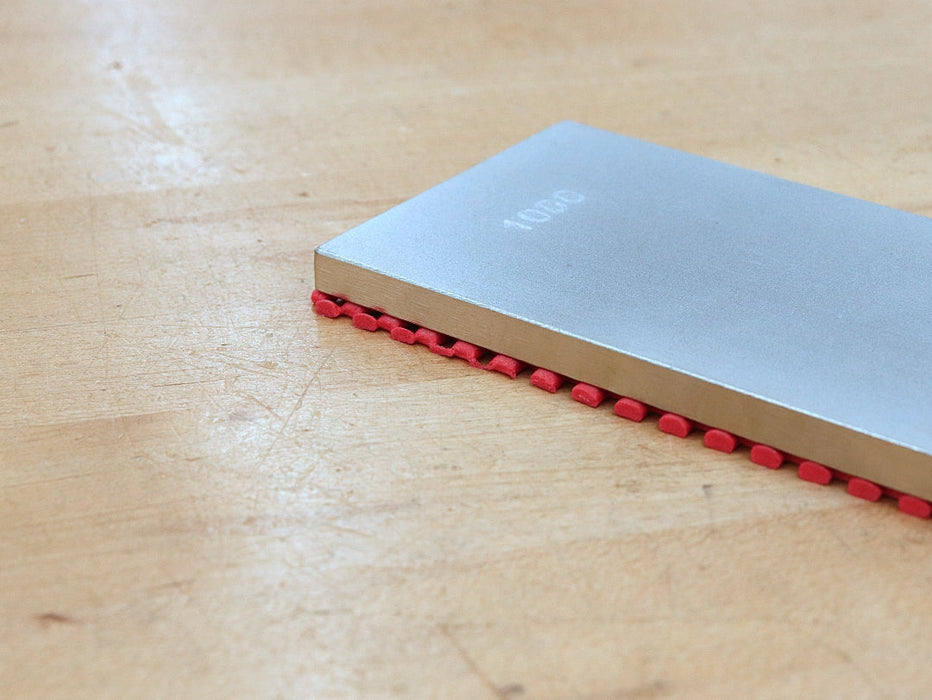

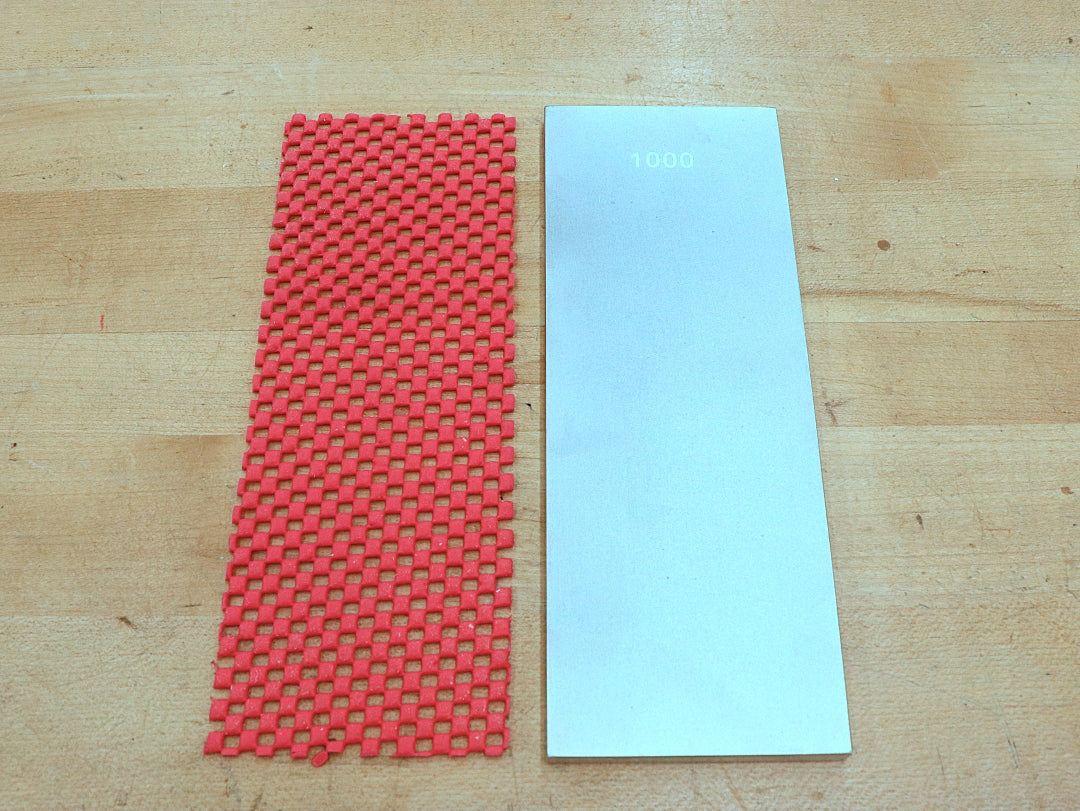

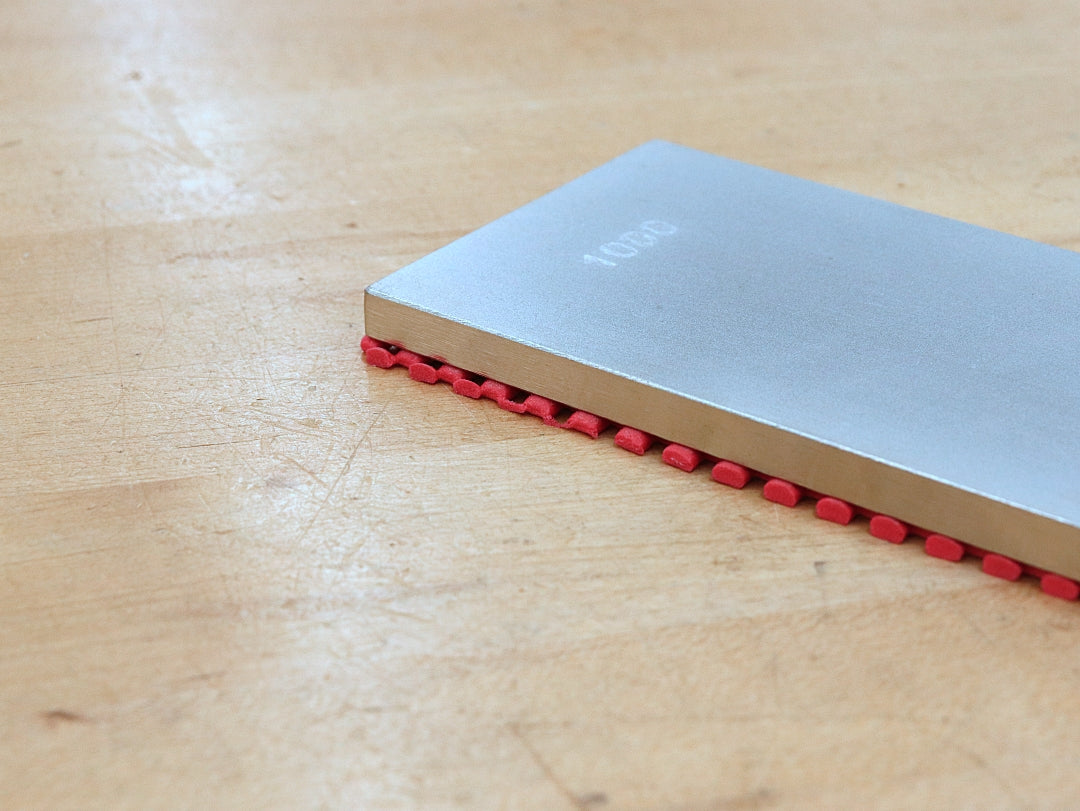

Precision milled, double-sided diamond stone 3" wide x 8" long.

- Electroplated with Monocrystalline industrial diamonds.

-

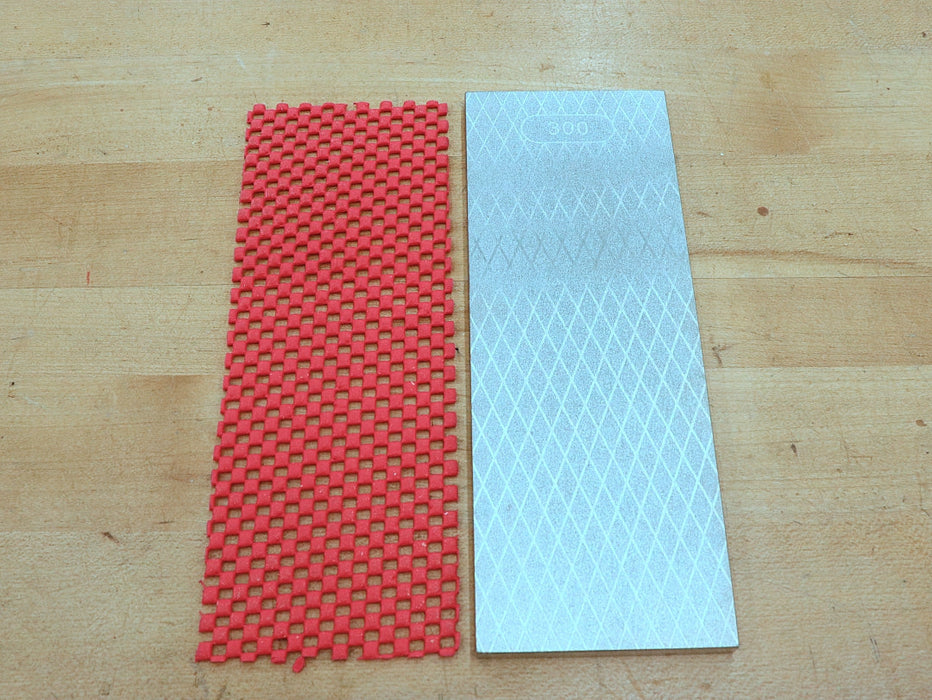

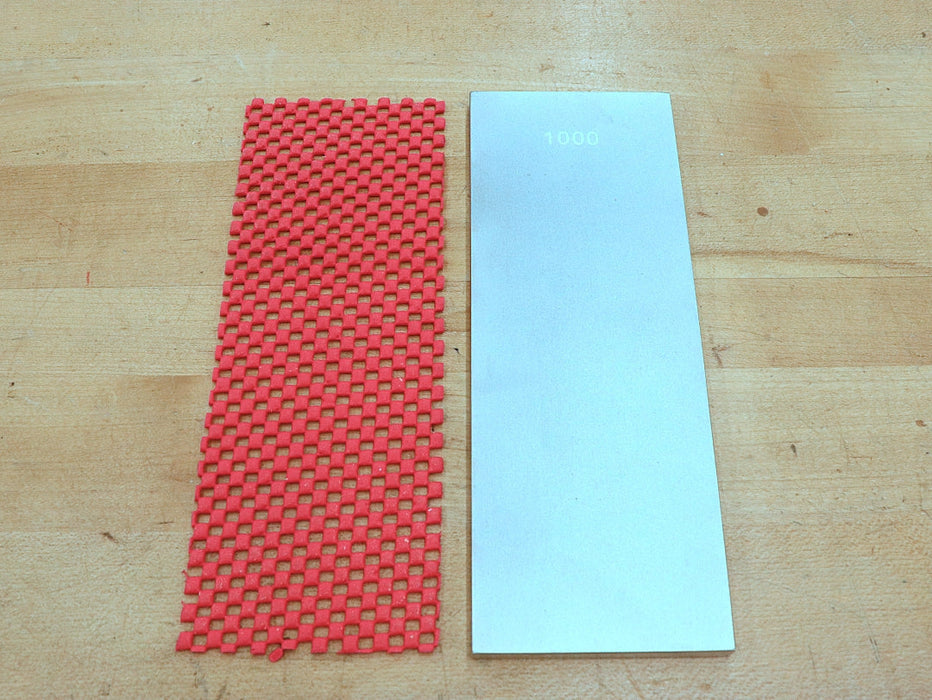

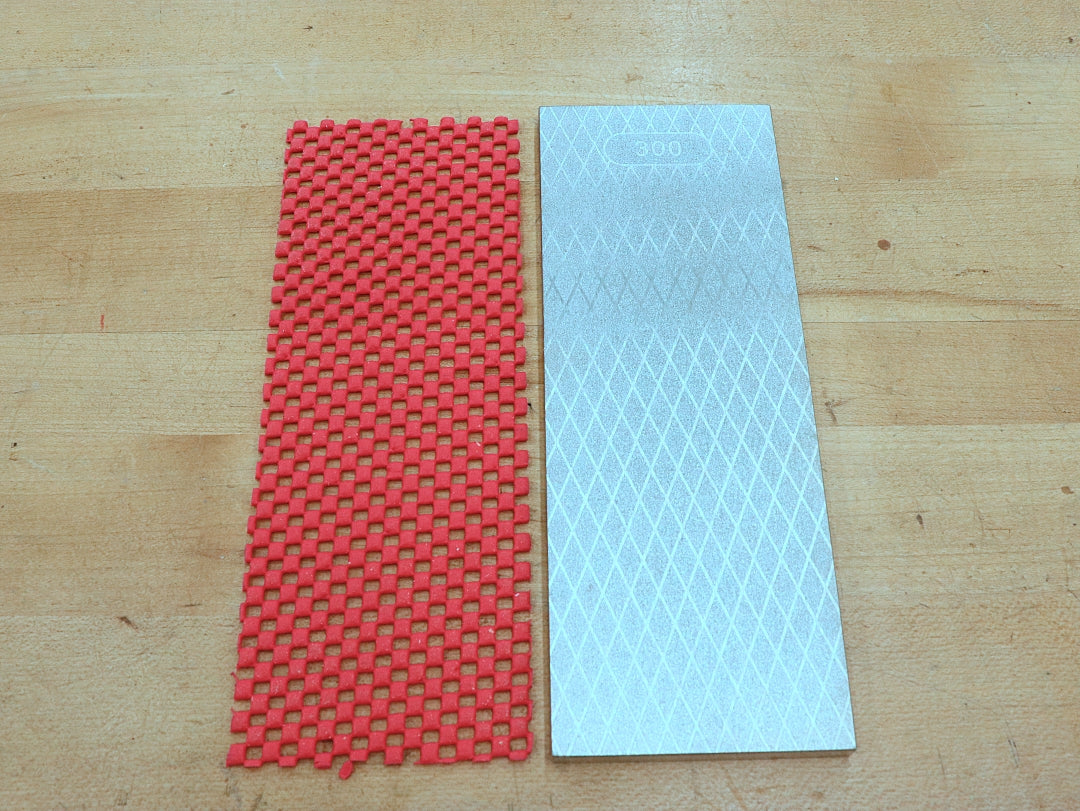

Fine 1000 grit (5 micron) on one side and coarse 300 grit (50 micron) on the other.

-

Clearance channels on the coarse side produces a faster, cleaner cut.

-

Use the coarse side for flattening your water / ceramic sharpening stones and on your chisel and planes when you need some aggressive cutting action.

-

Use the fine side for sharpening your secondary bevel on plane blades and chisels and other edge tools.

-

Comes complete with a non-slip mat.

One-Time Break-in Procedure: The 300 grit side of our diamond stones requires a one time break-in procedure. There is an excess layer of diamonds which needs to be removed before the surface is at its optimum. Break-in the stone by rubbing a piece of steel (a screw driver shaft, plane blade, etc.) over the entire surface of the 300 grit side for 1 minute. Rinse and wipe off the diamond stone; it is now ready to use. Failure to break-in the 300-grit side can lead to cross-contamination of water stones.