Gallery

Full Description

Customer Reviews

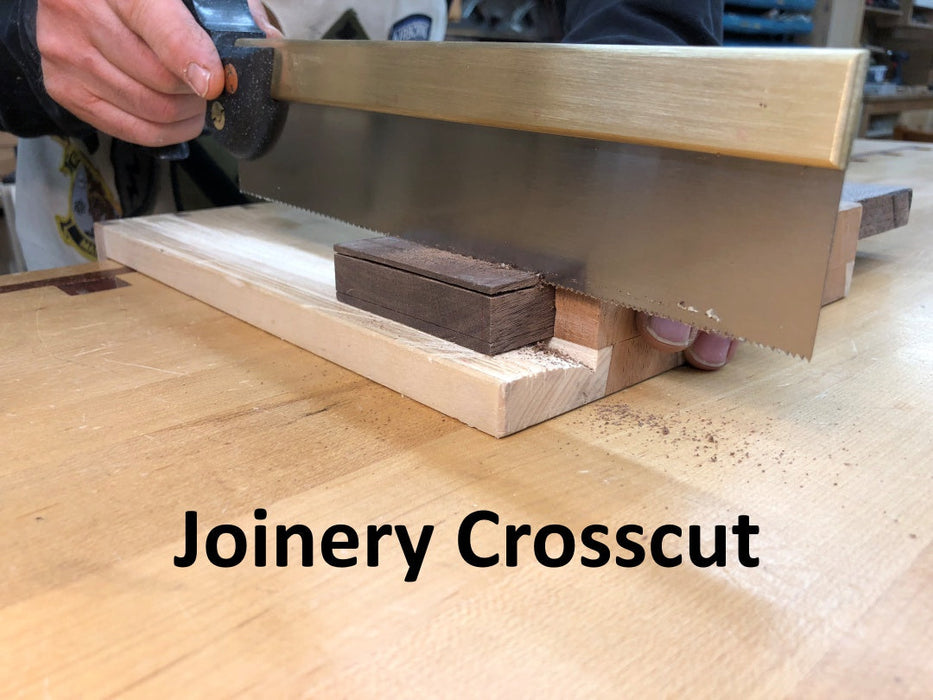

Every hand-tool woodworker needs a minimum of three backsaws: Dovetail, Tenon, and Crosscut Saws. I designed and manufacture two different Crosscut Saws: my Joinery Crosscut and my Bench Crosscut to meet this requirement.

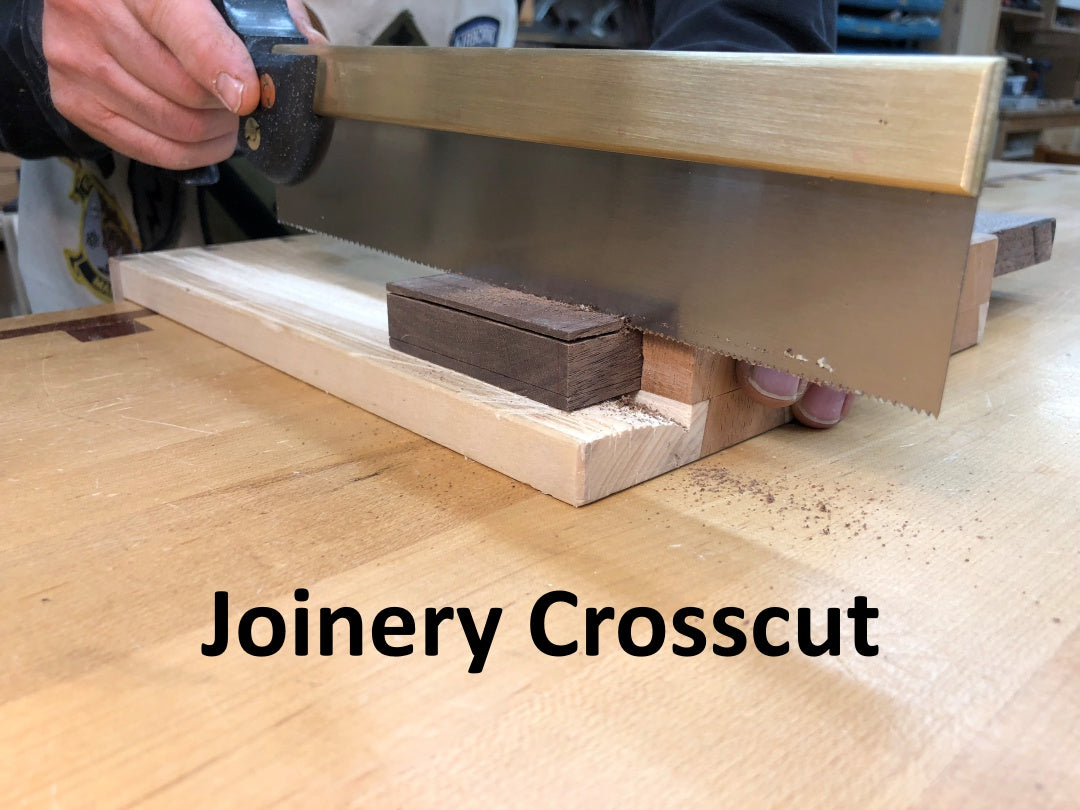

Both of my crosscut saws are specialized for crosscutting applications. My Joinery Crosscut Saw is designed for making finished, ready-to-glue joinery cuts. My Bench Crosscut Saw is designed for general cross cutting tasks.

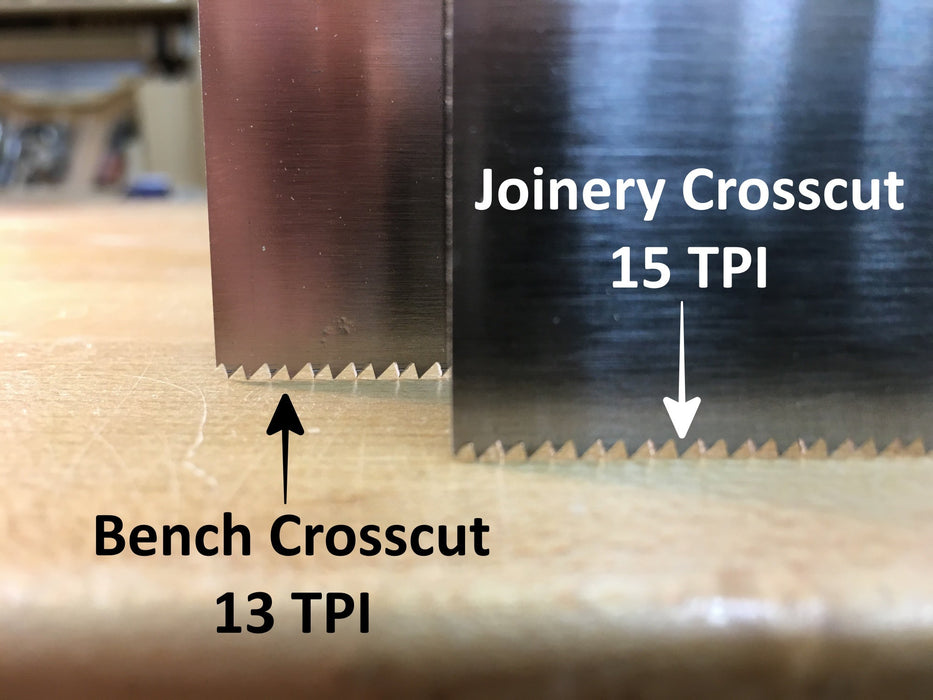

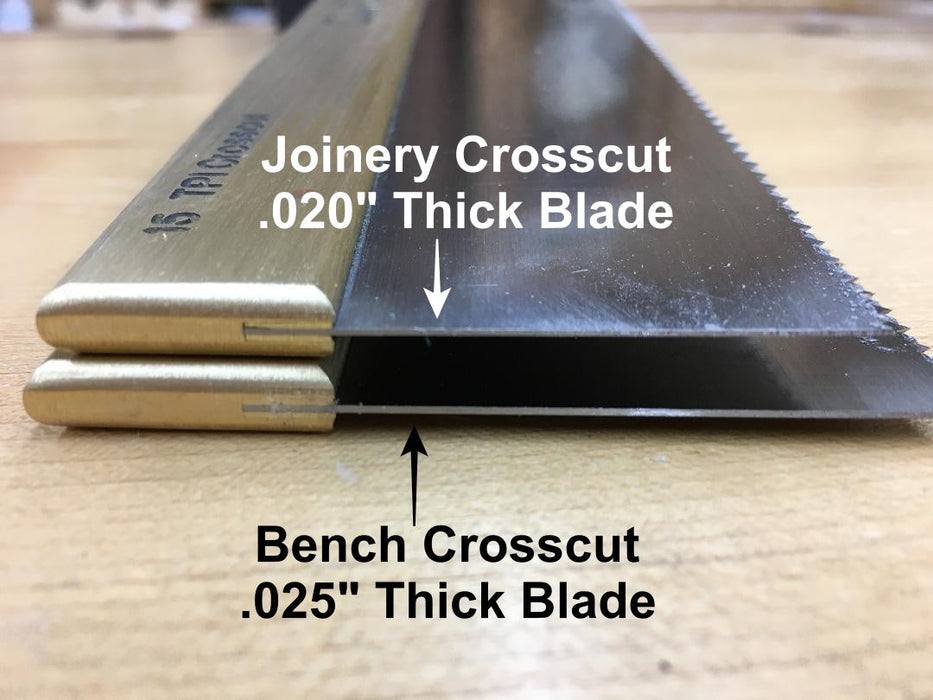

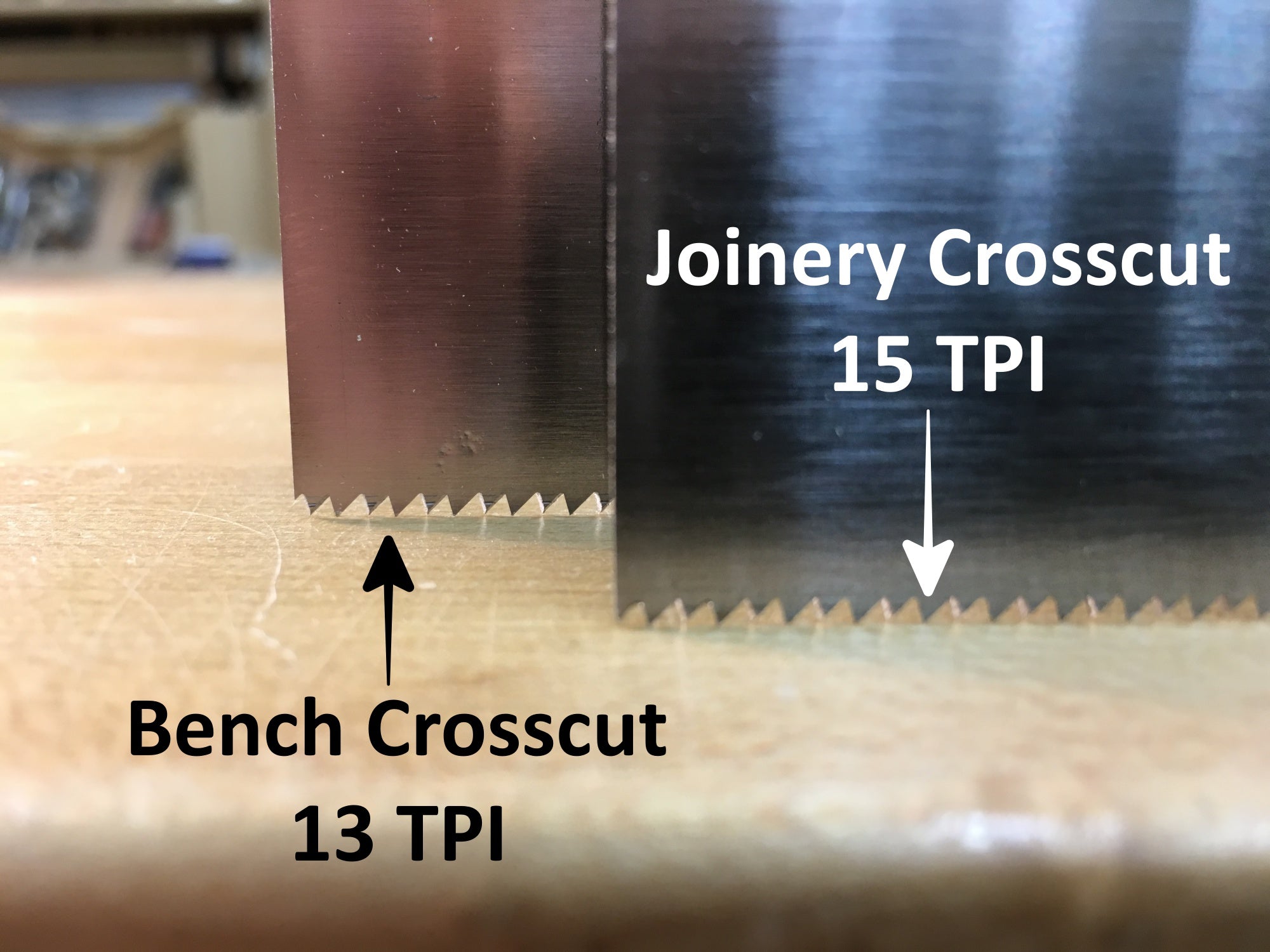

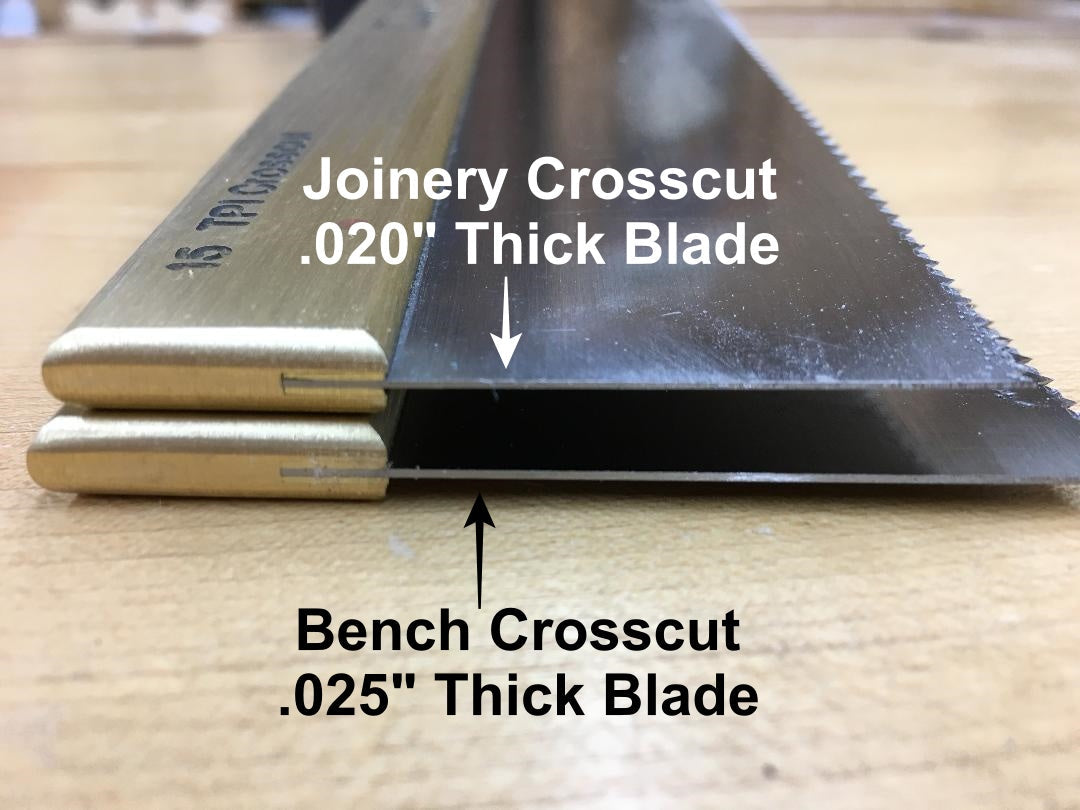

I designed my Joinery Crosscut Saw with a thin .020 inch blade, fine 15 tpi teeth filed crosscut, and a minimal .002 inch set per side. The teeth, formed with a diamond-saw, slice cleanly and precisely through cross-grain wood fibers.

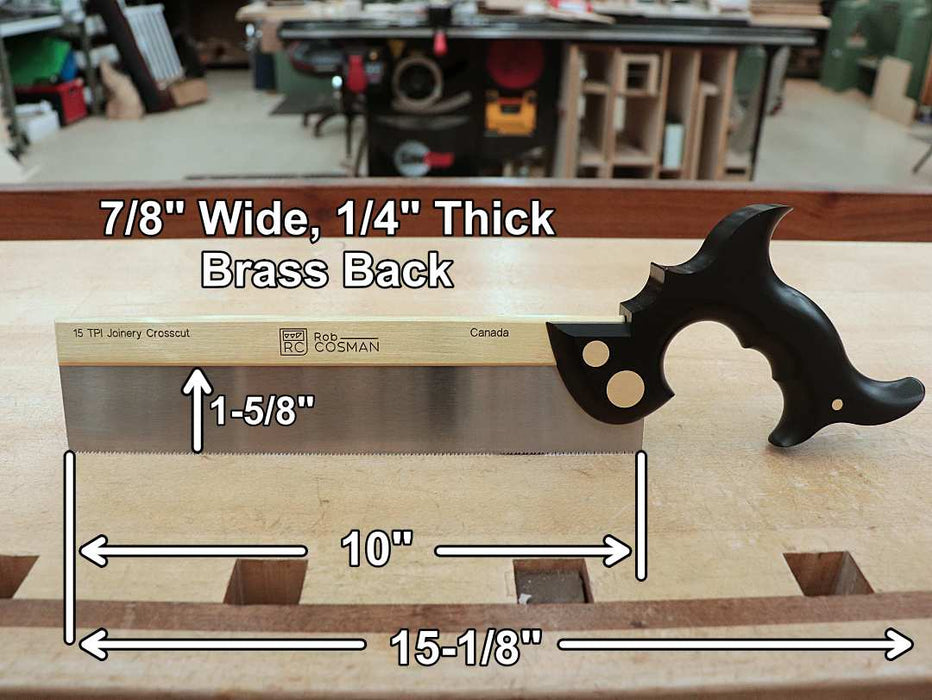

The minimal set creates a small kerf that guides the saw straight in the crosscut while the shallow 1-5/8 inch depth of blade (tooth-line to brass back) helps with stability while sawing to a line. The pistol grip handle conforms to your hand for a perfect, repeatable fit every time.

Both of my saws are specialized for crosscutting applications. The teeth, formed with a diamond-saw, slice cleanly and precisely through cross-grain wood fibers. The minimal set creates a small kerf that guides the saw straight in the crosscut. The shallow depth of blade (tooth-line to brass back) helps stability while sawing to a line. The pistol grip handle conforms to your hand for a perfect, repeatable fit every time.

Product Details:

-

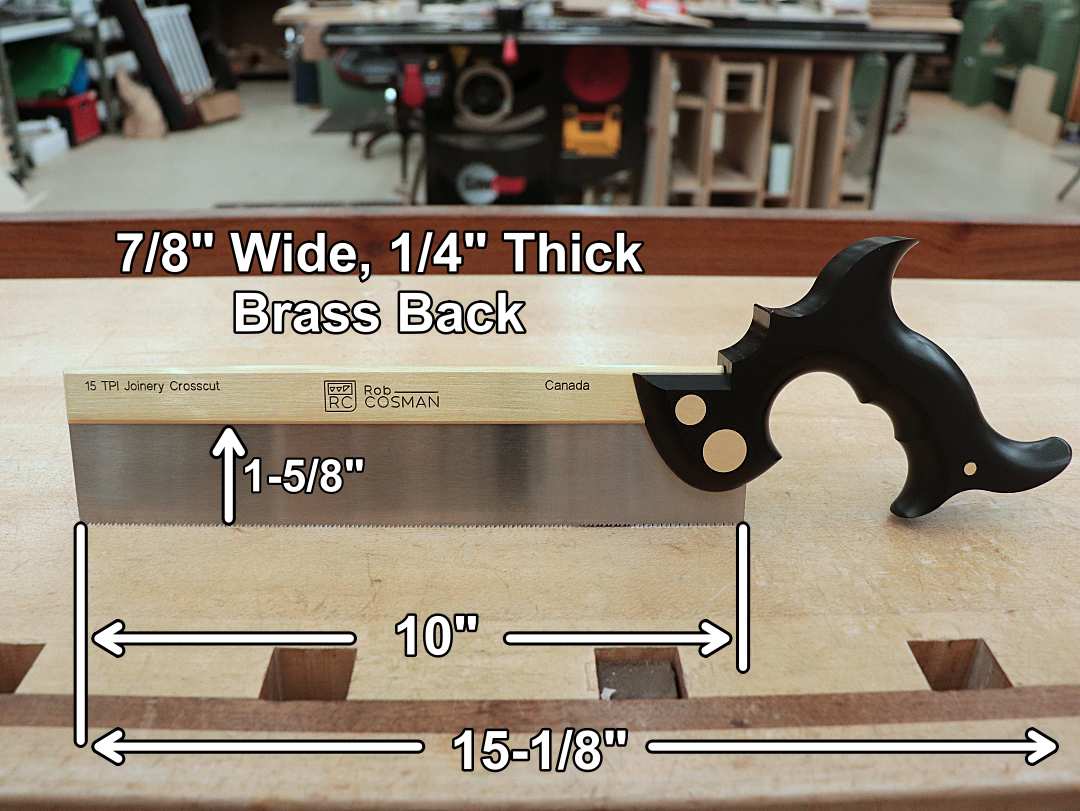

Size: Overall length (Toe to handle tip): 15-1/8 inches. Blade length (Toe to heal): 10 inches. Depth of blade under the back: 1-5/8 inches.

-

Weight: 18-20 ounces.

-

Blade: Made from .020" thick, spring steel.

-

Tooth Geometry: Filed crosscut at 15 teeth per inch (TPI) and a 0 degree tooth rake.

-

Set: Unlike most saw manufacturers who stamp out their saw teeth, leaving "dimples" in the blade, we individually cut out each of our saw teeth with a diamond saw. This allows us to maintain a very slight set of only .002 inch (per side), since we don't introduce that "dimple" onto the blade. This slight set produces a narrow .024 inch kerf that eliminates slop allowing the saw blade to accurately track in the saw kerf resulting in dead straight saw cuts with smooth ready to glue surfaces.

-

Brass Back: The brass back is 1/4″ thick x 7/8″ wide and is secured to the blade with peened and flushed copper pins. Not only does the brass look wonderful it imparts extra weight to the saw providing you a better balanced saw. This enables the saw to do the cutting work and helps you "feel" perpendicular.

-

Handle: Each of our "pistol grip" handles have memory enhancing carved finger recesses for a perfect and comfortable fit. A pair of brass split nuts secures the handle to the blade and the brass back. Our handles are made from Richlite, an incredibly durable, sustainable, and versatile material made from High-grade FSC-certified paper infused with a thermosetting resin.

-

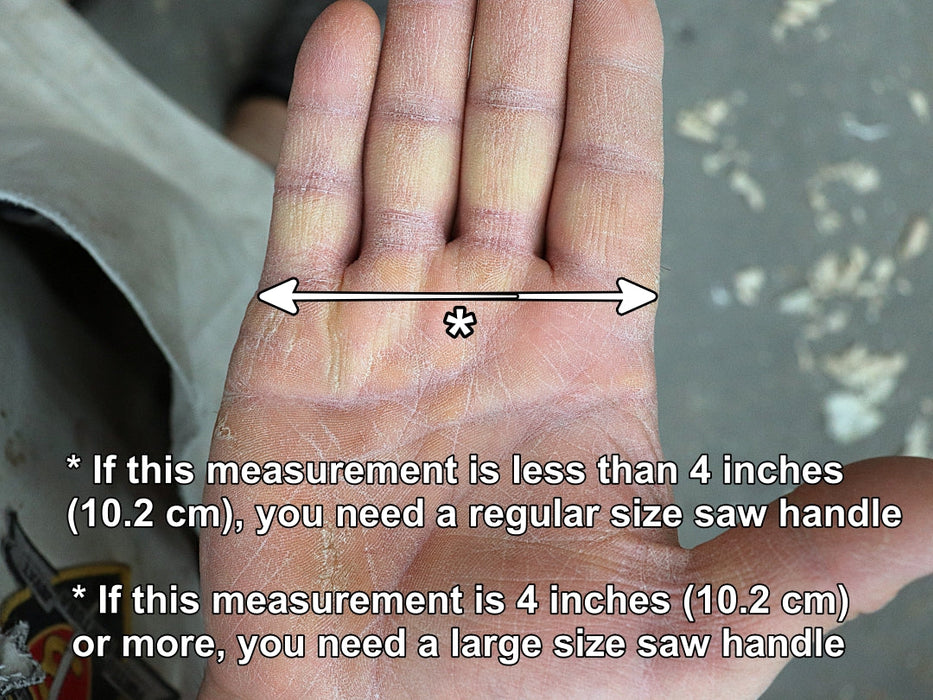

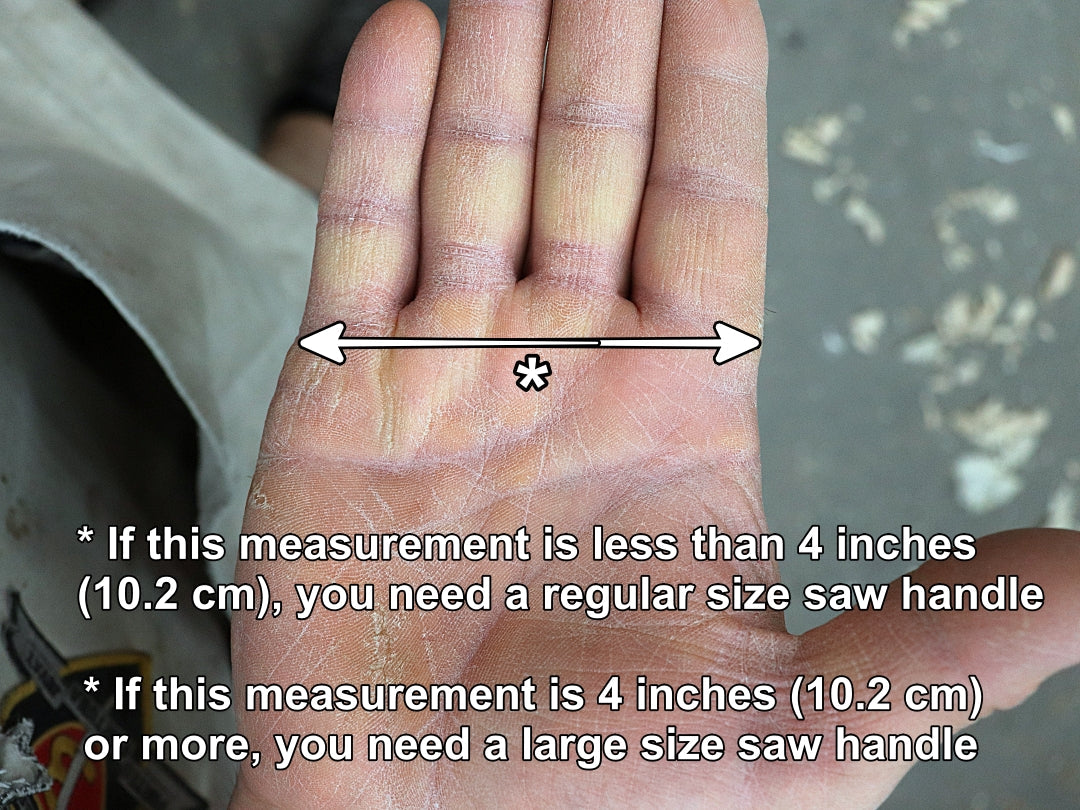

Handle Size & Determining your Size: Our handles come in two sizes: Regular and Large. Please refer to the picture above showing how to measure your hand and determine what size handle is correct for you size hand.